Feature:

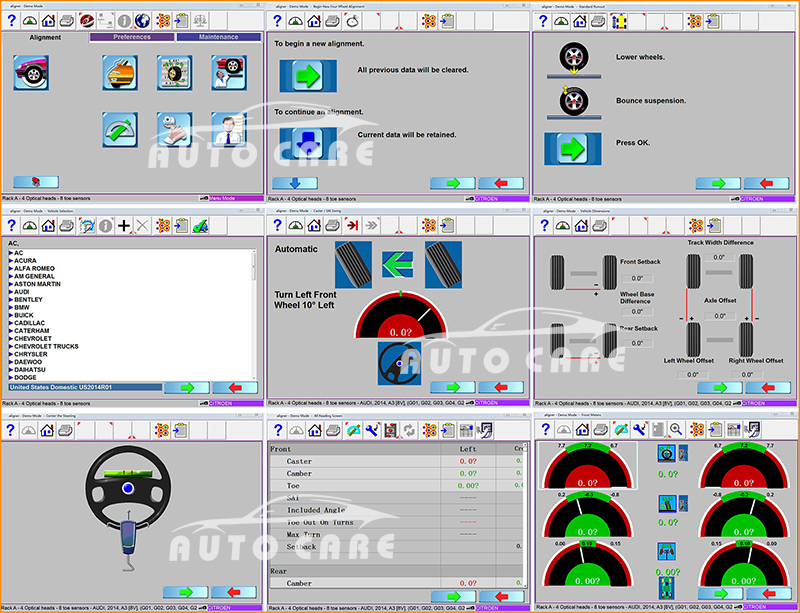

1.Windows 7 System,operation process can be easily guided by "Next step" instruction.

2.Exceed 20,000 data base around the world and with a life time update service.

3.Repeat measurement accuracy is ± 0.01,which be a world's leading level.

4.Measurement Angle: Toe, Camber, Caster, S.A.I, thrust angle, Setback angle, Max turning angle, Wheel tread, Wheel base,Wheel rolling redius.

5.Humanized software design,animation video can be used to help technician more quickly complete the operation.

6.Ultra-low chassis and refit vehicle—Volks Wagen and Audi, XLWB and with ESP function vehicle are also can be measured.

Standard configuration:

1.Apply high strength plastict arget,which is lighter,thinner and stronger.

2.Fast installation,suitable for all rims between12”-23”.Double chuck,which can install both on iron and aluminum wheel hub.

3.5 million high definition camera:it can also assure accurate alignment measurement when target plates get smaller.Intelligent LED navigation system:the operator doesn’t need to check the screen for the instruction of intelligent LED navigation system and can easily complete wheel alignment operation.

4.32” Main display LCD can make sure the operator clear recognize the data on the screen in any angle and condition during operation, thus improving the working efficiency.

5.Vehicle data update with free charge. Customers can download the software “ALPEMIX”, and our engineers will remote on line updation.